*

Prior

to

the

installation

of

HydroFLOW,

the

conductivity

of

the

cooling

tower

was

maintained

at

roughly

1,500

µS

via

constant

blow

down

(opened

drain

valve).

The

goal

was

to

maintain

conductivity

between

1,500

to

1,800

µS

while

reducing

water

usage

by

up

to

50%

and

keeping

the

cooling

tower

free

of

scale

accumulation.

Note:

Since

the

automatic

blow

down

mechanism

was

not

opera;onal,

blow

down

was

reduced

by

slightly

closing

the

valve

every

1-2

weeks.

Other

readings:

Iron

-

Fluctuated

between

0.00

to

0.07.

Alkalinity

-

Started

at

240.

One

week

after

HydroFLOW was

installed

it

reduced

to

180

and

remained

at

that

value.

Nitrate

-

Fluctuated

between

560

to

640.

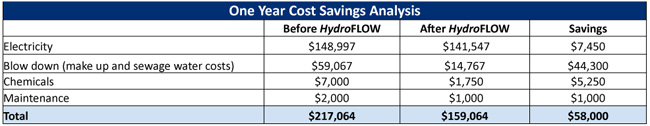

Results:

1.

Lime

scale

accumulaVon

stopped

as

soon

as HydroFLOW was

installed.

2.

Anti-scalant

and

Anti-corrosive

were

completely

discontinued

after

1.5

months.

3.

ExisVng

scale

and

biofilm

deposits

were

gradually

removed.

4.

After

reducing

the

biocide

by

75%,

the

total

bacteria

counts

conVnued

to

be

minimal.

5.

Blow

down

was

reduced

by

75%.

Note:

Blow

down

can

be

reduced

further

with

10%

side

stream

filtration.

6.

Efficiency

of

chillers

was

maintained

(no

scale

and

biofilm

accumulaVon

in

chiller

tubes).

7.

Under

one

year

Return

on

Investment

(ROI).

|